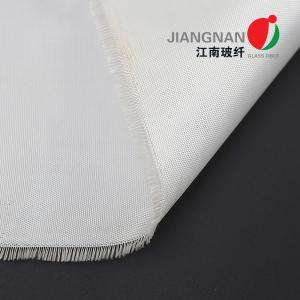

High Density Ultra Thin Fiber Glass Fabric Reinforcements Fiberglass Cloth

1. Descriptions:

Glass fiber cloth is mainly used in thermal insulation, fire prevention, and flame retardant. It can absorb a lot of calories and prevent flame through, cutting off the air. Glass fiber cloth is used for Hand Lay-up, mainly in hulls, cooling towers, storage tanks, vessels, vehicles, tanks, and the structure of the building materials.

2. Specification

| Specification-1080 |

| NO. | Technical Data | SI Units | US System |

| 1 | Weave Style | Plain | |

| 2 | Fabric Weight | 48g/m2 | 1.41oz/yd2 |

| 3 | Width (cm) | 107 127 157 |

| 4 | Length (m) | 2500 | |

| 5 | Yarn Density |

| Ends Warp | 23.6/cm | 60/in |

| Picks Weft | 18.5/cm | 47/in |

| 6 | Yarn | | |

| Warp | EC5 11 | ECD 450 1/0 |

| Weft | EC5 11 | ECD 450 1/0 |

| 7 | Breaking Strength |

| Warp | 210N/cm | 120lbf/in |

| Weft | 157N/cm | 90lbf/in |

| 8 | Thickness | 0.06mm | 2.3mils |

3. Factors of Scoring In Quality Control

- We have our own factory in Shandong to produce alkali-free and medium-alkali glass fiber yarns, which are sent to the glass fiber cloth production plant in Changshu every week. We will control the quality and price from the source of the glass fiber cloth

- We have our own laboratory for product quality testing. We will select 50 meters for testing for every 1000 meters of fiberglass cloth. Each product has corresponding indicators. Only when all the inspections are qualified, we will send the goods to the customer, when we encounter products with unqualified quality, we will destroy them. The testing content includes Weft and Warp tension force, Weft and Warp density, Thickness, Width, Length, temperature resistance, electrical conductivity, and cloth surface quality inspection.

- If any testing data is less than the specified testing content, the roll will be rated as unqualified.

- Our company has Oven to test the Heat resistance temperature for each product by customer orders.

- Jiangnan oven Fiberglass Cloth is wound into a roll on a cardboard inner tube with an inside diameter of 10cm (4"). Each roll is wrapped with a plastic bag and placed in a cardboard box. 12 or 16 boxes are placed horizontally on a pallet, which is stretch-wrapped.

- The fiberglass yarns are supplied by ourselves, it is more 20% strength and beautiful surface than normal fiberglass yarns,

- Our material factory locates next to a power station, so we produce glass fiber with low electricity and low water cost.

4. Product Application

Style 1080 1.4 oz. E-glass is a lightweight plain weave fabric woven. It can be used as the surface layer in the vacuum bag structure to obtain a smooth surface. It is an excellent multi-purpose lightweight glass fiber used for finishing surfaces and inside molds because of its high durability. At the same time, It uses epoxy resin and polyester compatible surface treatment to enhance wettability and is suitable for wet lamination, vacuum bagging, and resin infusion manufacturing.

5. Product Features

Improve Surface Toughness and Strength, Light Drape, High tensile strength, Dimensional stability, High heat resistance, Fire resistant, Good thermal conductivity, Good chemical resistance, Outstanding electrical properties, Durable, Economical

6. More Pictures for Product and Package

7. Related Products (Fireproof Fabric Series)